How to use an eye wash station: User Guide

What is eye wash station? An eye wash station is an emergency shower system designed to wash away the foreign substance instantly before you can receive medical treatment. Eye wash station is widely used in dangerous and corrosive environment, for instance, lab, chemical factory, and painting factory. An eye wash station has many advantages over portable eye wash. An eye wash station can provide over 15 minutes of shower time and it does not require daily maintenance. Please notice that portable eye wash is not considered a replacement for full eye flushing. In this article, we are going to introduce you the ANSI eye wash station standards and how to install the eye wash station.

What is eye wash station? An eye wash station is an emergency shower system designed to wash away the foreign substance instantly before you can receive medical treatment. Eye wash station is widely used in dangerous and corrosive environment, for instance, lab, chemical factory, and painting factory. An eye wash station has many advantages over portable eye wash. An eye wash station can provide over 15 minutes of shower time and it does not require daily maintenance. Please notice that portable eye wash is not considered a replacement for full eye flushing. In this article, we are going to introduce you the ANSI eye wash station standards and how to install the eye wash station.

Index

- Eye wash station installation location & instructions

- ANSI eye wash station and requirement

- How to use eye wash station?

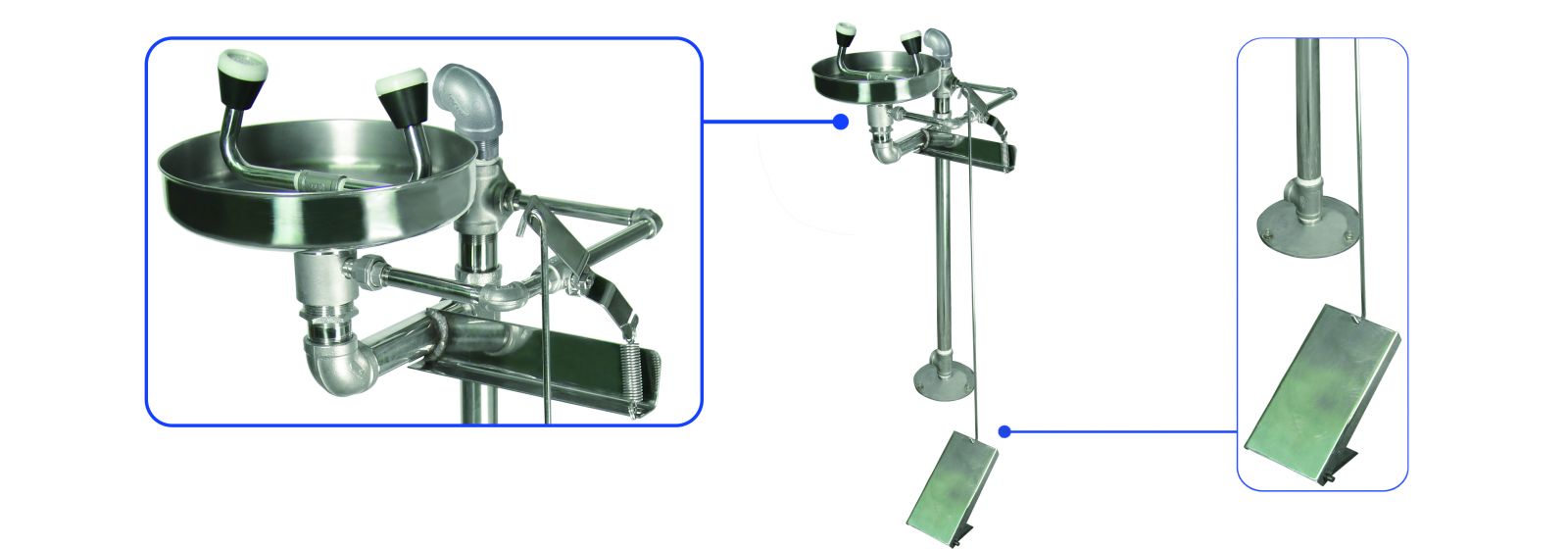

- GSE-series

- How to assemble eye wash station?

- Eye wash station maintenance

Eye wash station installation instruction & location

- Eye wash station must be installed within 10~30meters from the hazard. And the route should be unobstructed.

- There should be obvious sign telling where the eye wash station is and how to use it.

- Any kind of electric outlet or switch should not be presented with 1.5 meters from the eye-wash station.

- The water supply should be connected to clean water, and the water pressure should be no less than 1kg/cm2.

- The supply pipe should be 5/4 inch, and the drain pipe should be 5/4 inch.

ANSI eye wash station standards and requirement

Over 150 countries use the ANSI Z358.1, American National Standard for Emergency Eyewash and Shower Equipment, or similar standard to assess their eye wash station. The ANSI certificate should only be tested by a third-party assessment bodies. It provides uniform guideline for their performance, installation, use, test procedure, training, and maintenance. GoangJih’s eyewash station, GSE-1, is certified by Intertek and complied with ANSI/ISEA.1-2014. This is the latest ANSI version and has significant changes compared to the previous one. Choose GSE-1 and obtain the latest and fullest protection.

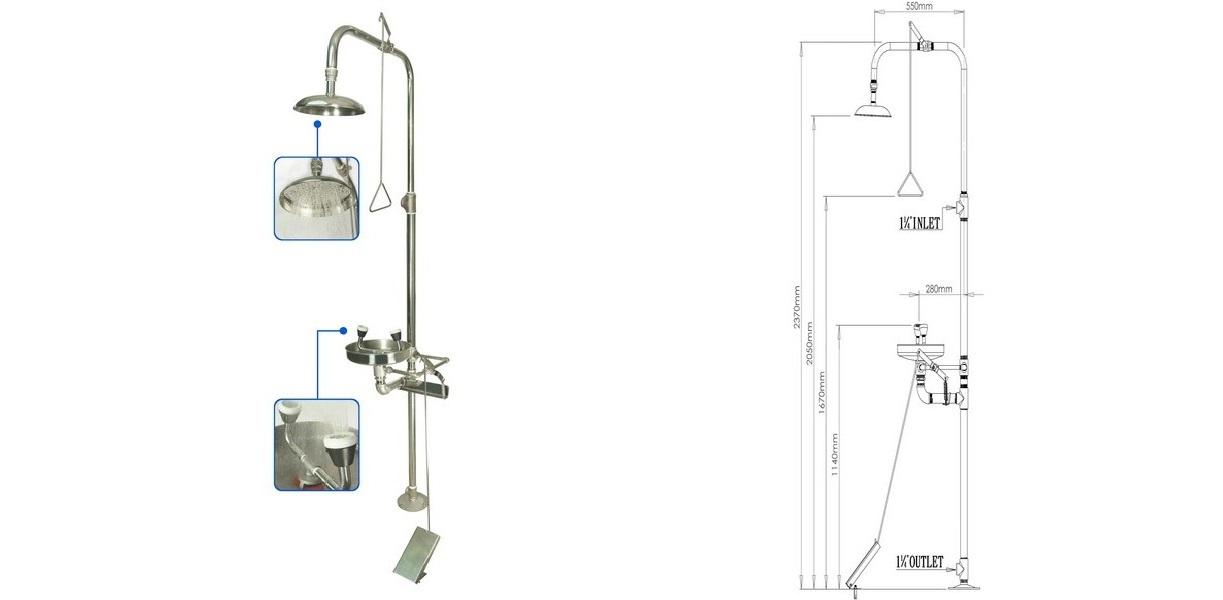

How to use an eye wash station & emergency shower system?

When the foreign substance splashed on your body, quickly go to the shower zone and pull the handle down to use the emergency shower system. You can take off your shirts if necessary.

When the foreign substance splashed in your eyes or face, hold your eyes open and step on the foot paddle to activate the eye wash station.

You can also use both eye-wash and shower systems at the same time. You should receive flushing for a full 15 minutes duration and seek medical help immediately after that.

How to assemble eye wash station?

1. Mount the stand to the floor and assembly the combination units following the instruction orders.

2. Seal the pipe threads with thread seal tape (PTFE tape or Teflon tape) to prevent leaking.

3. Finally connect the water supply pipe and drain pipe with GSE-1 and ensure the water is to flow out freely and waste exit properly.

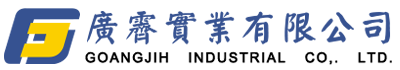

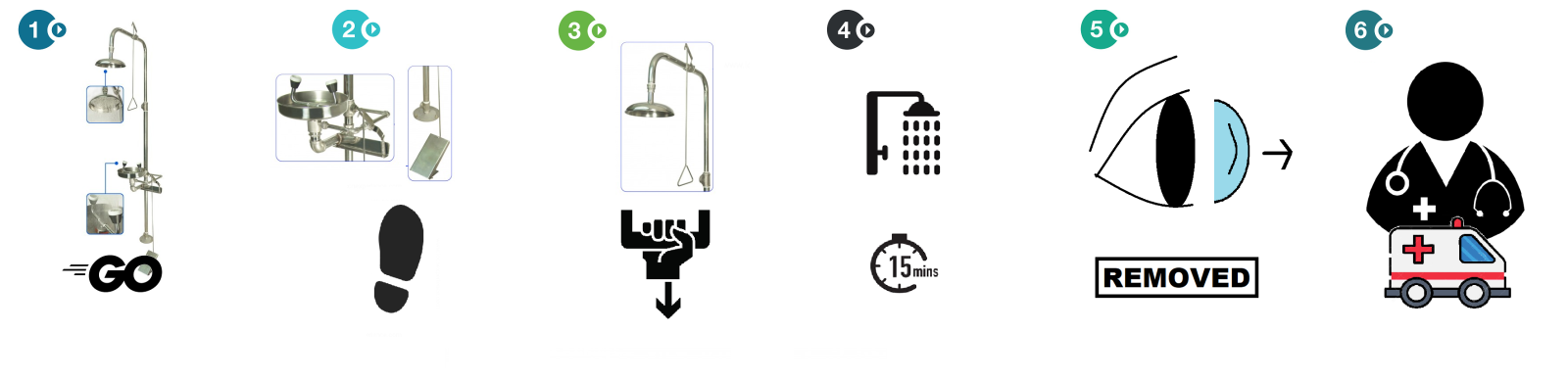

GSE-series

GSE Eye wash stations and emergency shower has been certified by Intertek to meet the ANSI Z358.1-2014 standard for emergency eyewash and shower equipment. It is available in over 150 countries. It is perfect to install in laboratory, hospital, chemical plant, painting factory and any other corrosive and injurious environment.

Model: GSE-1

Construction: SUS304 Stainless Steel

Supply Pressure: 2~4 kg/cm²

Shower Flow Rate: 80L/min (21 gpm)

Eye Wash Flow Rate: 35L/min (9 gpm)

Test Pressure Flow Rate: 3 kg/cm²

ANSI Z358.1 tempering compliance

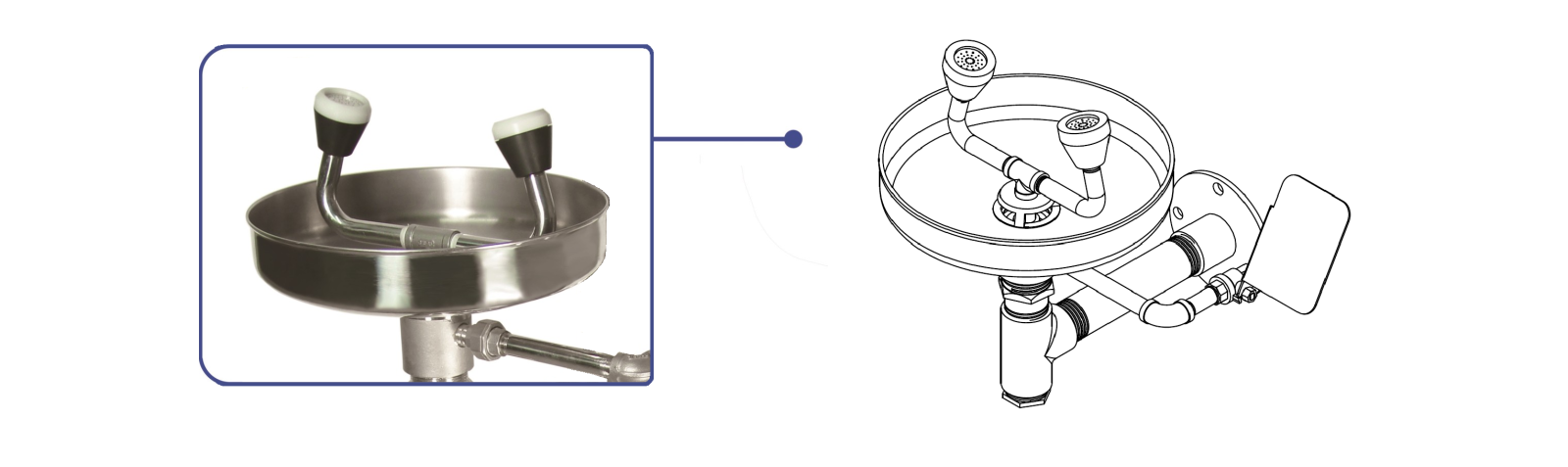

Model: GSE-2

Construction: SUS304 Stainless Steel

Supply Pressure: 2~4 kg/cm²

Eye Wash Flow Rate: 35L/min (9 gpm)

Test Pressure Flow Rate: 3 kg/cm²

ANSI Z358.1 tempering compliance

Model: GSE-3

Model: GSE-3

Construction: SUS304 Stainless Steel

Supply Pressure: 2~4 kg/cm²

Eye Wash Flow Rate: 35L/min (9 gpm)

Test Pressure Flow Rate: 3 kg/cm²

ANSI Z358.1 tempering compliance

Eye wash station maintenance and inspection

GSE-1 eye wash station is constructed with 304 Stainless steel and virtually does not require maintenance. But we still recommend to carry out the following inspection and training procedures.

- Activate the eye wash station weekly to ensure its functionality.

- Workers should be given the full instruction about how to use the eye wash station.

- Inspect all eye wash station units annually for compliance with ANSI Z358.1-2014

If you need more information, please contact us via email or phone. We will contact you as soon as possible.